Copyrights 2018 power poles beipiao manufacturing co.,ltd 辽ICP备2021000339号-1 Powered by www.300.cn jinzhou.300.cn

Beipiao Power Pole Manufacturing Co., Ltd. has the production capacity of prefabricated building-specific components

In 2018, Beipiao Electric Power Pole Manufacturing Co., Ltd. is preparing for the operation of the assembly-type construction production base project based on the production of traditional concrete products. The investment in the first phase of the project is planned to be 65 million yuan. According to the assembly rate of 30% of houses in Chaoyang area, the production scale of 60,000 m3 per year is formed. New concrete prefabricated parts such as stairs, wall panels, laminated slabs and shear walls. At present, the above products have been successfully trial-produced. It is estimated that after the completion of the project, the annual output value will reach 200 million yuan, the profit and tax will be 30 million yuan, and 200 people can be employed. The progress of the project and the scale of production will increase investment according to the promotion of local governments and market demand.

Beipiao Power Pole Manufacturing Co., Ltd.

Self-production and installation of the model room (real shot effect)

The PC component manufacturing of this model is based on the “National Building Standard Design Atlas 15G365-1” and “Precast Concrete Shear Wall Exterior Wall Panel”. The outer wall panel size is 3000mm*2760mm, and a total of 8 prefabricated, of which 2 are with windows. Sandwich "shear wall siding, 2 pieces of "sandwich" shear wall siding with door opening.

According to the “National Building Standard Design Atlas 15G365-2” and “Precast Concrete Shear Wall Interior Wall Panel”, the interior wall size is 3000mm*2760mm, totaling 2 pieces.

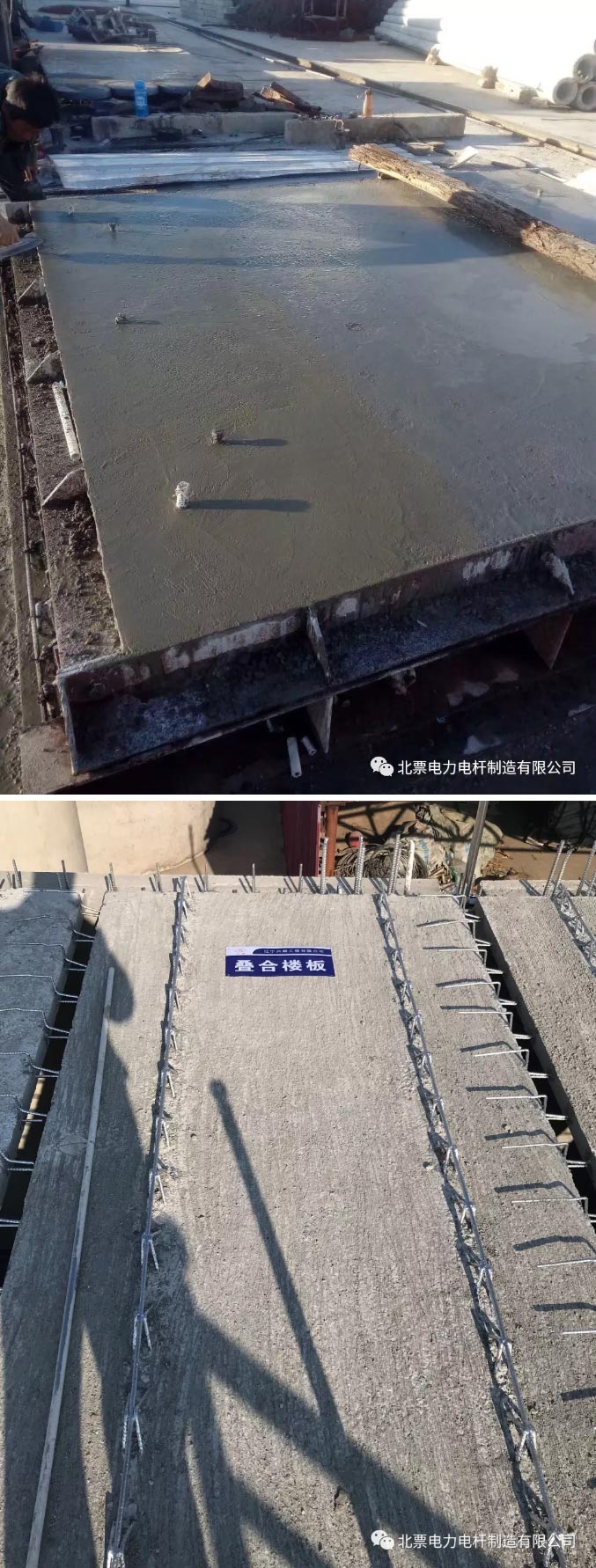

According to the “National Building Standard Design Atlas 15G366-1” and “Terminal Reinforced Concrete Laminated Plates”, the required size of this sample room is 915mm*3060mm, 1480mm*3060mm, and the prefabricated plate thickness is 60mm. A total of 6 pieces are prefabricated.

According to the “National Building Standard Design Atlas 15G367-1” and “Prefabricated Reinforced Concrete Slab Stairs”, the required staircase size of this sample room is 2900 standard floor height and 9 pedal stairs, totaling 2 pieces.

Manufacturing mode:

1. Main materials: C40 concrete, HRB400 hot-rolled ribbed steel, HPB300 hot-rolled round steel, EPC external wall insulation board, junction box, threading pipe and other embedded components.

2. The inner and outer walls, stairways and laminated slabs of the prefabricated shear wall of the sample room are all produced by fixed die table mode. The advantages of this production mode are low investment, accurate size, low production cost and flexibility.

3. The assembly method is installed by special lifting tools such as manual and crane.

4, the basic process of the production line: mold table cleaning process → spray release agent process → installation side mold reinforcement installation pre-buried process → concrete pouring vibration → surface treatment process → curing process → mold removal process → component uplift, lifting Process → component factory transportation process.

Compared with traditional cast-in-place reinforced concrete and masonry buildings, prefabricated buildings are manufactured by prefabricating building components including beams, slabs, columns and external walls. After curing and acceptance, they are transported to the site. The construction method in which the installation is completed. It is a new type of building structure that is actively promoted by the state, green, energy-saving and environmentally friendly. Shear wall, staircase, balcony, laminated floor and other factory production, accurate component size, quick on-site assembly, convenient, strong shock resistance, safe and durable.